R.I.E

Process

-Dry texturing

-Black Silicon

Applications

-Solar wafer texturing

Introduction.

RIE is used to reduce the reflectance of wafer in solar industry. IPS RIE is the only dry etcher being used in mass production line of multi-crystaline wafer. Recently IPS RIE has increased etching rate as 1.5 times by applying new plasma source called "Grounded mask" so secured competitiveness to substitute wet etcher. Before long IPS RIE will replace the wet ething process in solar industry.

Technology.

RIE(Reactive Ion Etching) Dry texturing process to make the surface of solar wafer rough by forming pyramid shape texture. To increase the cell effiency of solar cell the bigger pyramid shape texture is needed.

Features.

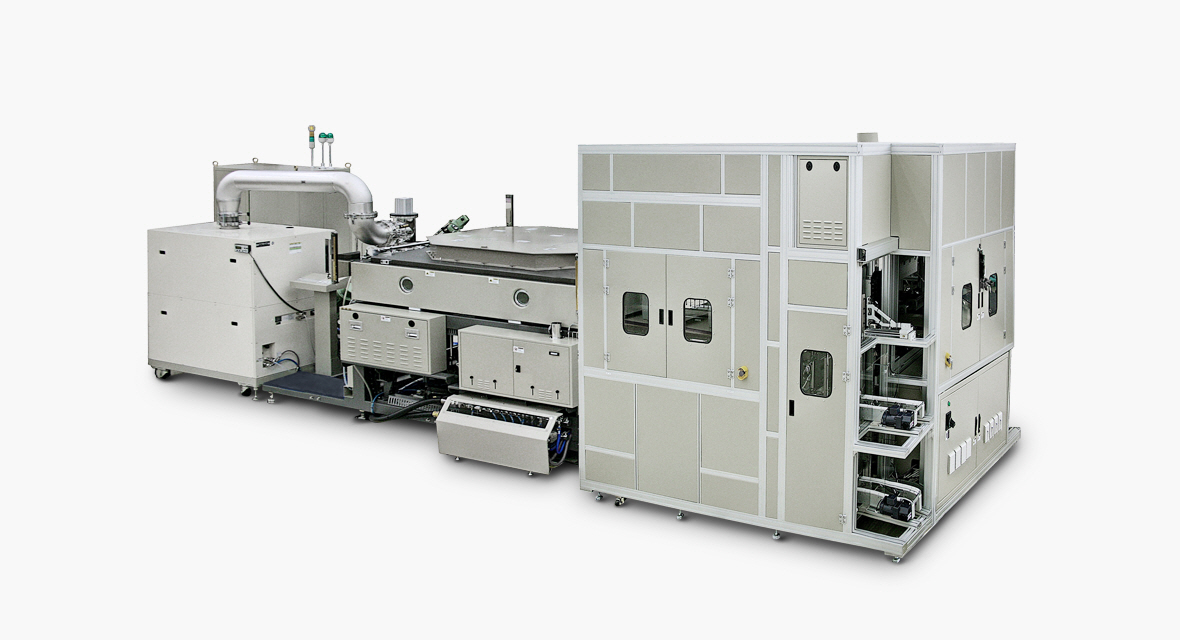

1. Planar CCP plasma mode(13.56MHz single RF) 2. 10*10 wafers(156mm*156mm) loading in a batch 3. High etching rate and uniformity by grounded mask 4. High uptime rate by cluster type system 5. High throughput by dual arm picking system

Product and technical inquiries

TEL : +82-31-8047-7624 E-mail : solar@ips.co.kr